Eunice Chang

Technology for Living - Professor Chenming Hu

University of California, Berkeley

Electrical Engineering and Computer Science

Project Date: March 1998-October1998

Background

The story behind this project started when someone called a staff person in our department. She said she had read about the Technology for Living group in a newsletter, which outlined a device that could detect volume and had flashing lights. She wanted us to build such a device for her daughter who is autistic and has difficulty controlling her voice level when she speaks. It turns out that the device that was built was a bulky device built by a previous student and we had no documentation or evidence of the device. So we set out to find out exactly what the client had in mind and what was available on the market.

The specifications that the client wanted were a small device that had lights to indicate the volume of speech. Preferably it could be small enough to be wear on the person and adjustable to difference noise thresholds in case of background noise. The device was to detect how loud someone was speaking and if this volume was higher then a set preferred level, some lights would go off as a warning.

Market Research

Given these very loose specifications, we set out to find something of this kind on the market. None of the things we found matched these specifications, but some of the commercial devices found include a decibel meters and industrial noise meters. The decibel meters were great for detecting noise level, but they were rather large handheld units with a numerical display of the noise level in decibels. There were many possible adjustments and display formats, but it could not be set to detect a certain noise level and it would be hard for a child to interpret the information. The industrial noise meter is employed in large factories to monitor noise pollution. It's sold as an expensive, extensive system that combines fixed monitors, data collection, and some portable noise level detection units. These devices were also very numerical in feedback and although they could be set to detect a certain noise level they were much too expensive for consumer use.

Since no commercial device could be found, the next best thing was to see if we could come up with a device ourselves by building our own circuits. Armed with my limited knowledge of circuits and product design at the time, I set out to find some sample circuits and get an idea of how to design the electronics.

Building Test Circuit

After some searching, I found some sample circuits in a Radio Shack kit. Using this as a guide and asking help from the staff in IESG (the instructional support group in EECS) and the people at the electronics stores, I attempted to build a volume level meter. After gathering all the basic parts, I built a test circuit on the breadboard and demonstrated it to the group. The circuit that I followed is shown in Figure1 on the following page and the values of the components are shown in Table1 below.

What this device does is to sample noise through an earphone that acted as a microphone, then rectify this signal with the diode, and finally compare the voltage level against four set voltage levels. The fixed levels were established by means of resistive voltage dividers. The fix value and the signal value were compared by op-amps and if the signal level was above the fixed level then an LED would turn on signaling that a particular threshold had been surpassed.

| C1 | 470 | pF | R1 | 220 | kW | R9 | 100 | W | ||

| C2 | 100 | mF | R2 | 3.9 | kW | R10 | 100 | W | ||

| C3 | 10 | mF | R3 | 75 | kW | R11 | 270 | W | ||

| C4 | 0.47 | mF | R4 | 2.7 | kW | R12 | 270 | W | ||

| C5 | 1 | mF | R5 | 47 | kW | R13 | 1 | MW | ||

| C6 | 10 | mF | R6 | 5.6 | kW | R14 | 10 | W | ||

| C7 | 0.1 | mF | R7 | 47 | kW | R15 | 68 | W | ||

| R8 | 3.6 | kW | R16 | 30 | kW |

Final Product

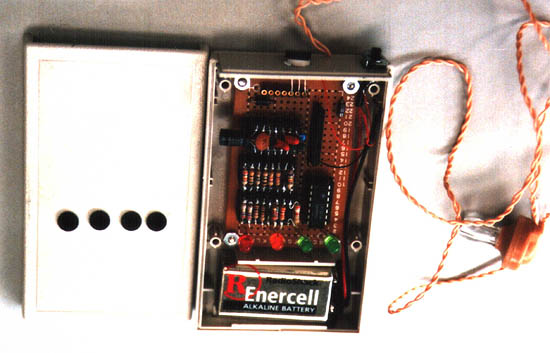

After some experimentation and consulting with the client, I went forward in designing a product that the client can use base on the test circuit. It was decided that the device would be made as small as possible so a small box was found that had a battery casing already designed into it. Then the circuit was soldered to components holder that could plug into wire wrap pins. The blocks of components were then assembled onto a blank PC-board. So on one side was the components, which plugged into the holes of the PC board. And on the other side wire-wrap was used to make all the connections. Below is a picture of the final product with the front cover off and the schematic layout of the components and wire-wrap connections. (The roman numerals indicate the pins of the amplifier and the Arabic numerals refer to the pins of the op-amp.) The lights show out the front and a small potentiometer on the side is used to adjust the sensitivity. A 9-Volt battery is put into place and can be replaced through a small removable door on the back of the device. The device is approximately the size of an average remote control.

The final device for some reason did not perform as well as the one on the breadboard. The only reason that I could find was the interference between the signals on the wires. There were some coupling of signals in the thin wire-wrap wires. I had tried to minimize this effect already by routing the high and ground wires away from the signal's wires, especially the one that carried the volume level signal to the comparator.

Client Feedback/ Future Revisions

After the product was finished, I showed it to the client and they were please to have a finished product, but the little girl did not like the device at all and was unwilling to even play with it. The parents had some suggestions like trying to make it smaller, without wires or microphones, and maybe trying to use something other than lights. For example use a vibrator or sound like a small beeper. All of these suggestions are valid and can be implemented in future projects if one wished to continue this project. My suggestion before anyone goes forth with this is to look at what's available on the market again to see if consumer products have improved. Then go from there and decide what's the best technical strategy. Another suggestion I have is to talk directly to the children who are involved instead of just the parents, because they are ultimately the consumers of the product and making something that children would like to use is, well, hard to say the least. This means that it's a good idea to know your clients very well and what they like, since we are free to customize products to suit a certain client.

| back to the home page |